In addition to the suction efficiency and non-invasive working distance, the technical application of the high flow concept ensures other strategic advantages for users, often required in the preventive phase but difficult to reach by low flow systems with small pipes and hoods

The dental aerosol extractor following the worldwide pandemia of Covid-19 has become an indispensable equipment for dentists and dental practices, in order to ensure contamination safety for both the patient and the operators.

With this article we want to technically address the problematic of the suction method that any professional is facing put in front of the aerosol problem : how can I aspirate it in the best way? And how can I do that without it being invasive for the patient but also for those who have to work many hours a day ? To help us in this technical examination we relied on the technical team of Dentalairsafe.com which developed and patented the AirSafe line products currently the only ones in the world that have faced the aspiration of dental aerosols in a complete way, up to propose not only portable extractors but also centralized systems with external purifiers.

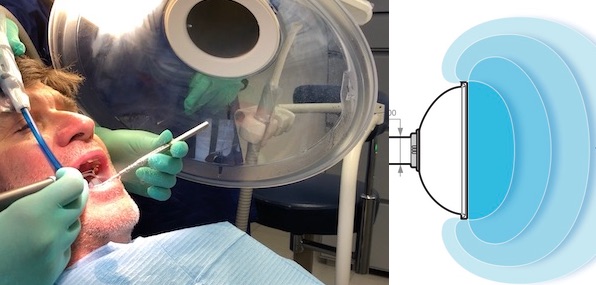

The high working flow rate of the aerosol extractor, when applied to a properly designed hood, creates a negative pressure in front of the hood, which can be represented aerodynamically as a semisphere having the same diameter as the circular hood, evident in the image on the side.

In the case of AirSafe® high flow systems this sizing was carried out trying to find the right compromise between the diameter of the hood that should not be too large and the aspiration and working needs of the technicians, in order to guarantee an effective capture of the aerosol but also of the extra oral nebulization that as we know is at 100% humidity.

| In contrast to the above, a low flow rate means having to work too close to the patient, normally these systems are distinguished because they have very small tubes and even hoods reduced to a minimum, otherwise aerodynamically they would not be able to generate any suction.

Here on the right an example of a system on the market, adapted to aerosol but difficult to operate. |

|

In addition to the suction efficiency and non-invasive working distance, the technical application of the high flow concept provides other strategic advantages for users, often required in the preventive phase but difficult to reach by low flow systems with small pipes and hoods:

| Reduced noise level of the aerosol extractor, because the air inside a large hood “enters” at reduced speed and for this reason there is less rustle. Obviously the pipes must therefore also be large, normally at least 10cm in diameter.

Air exchange within the operating study, in case of high flow rate in fact the aerosol extractor can/must be kept on even when you are not operating on the patient. In this way, airborne particles that, as we know, remain in the air for hours are sucked and filtered by the system.

|

|

Being a new application, as always happens in these cases, most of the products and solutions on the market are extractors designed for other laboratory uses, quickly readjusted to the aspiration of the extra oral aerosol for commercial reasons. At the same time, the various actors of this new application, that users and distribution networks of dental equipment are not very well prepared for the aspiration and filtration of air contaminated by particular airborne such as aerosols and for this reason a very dangerous market situation has been created, result in the use of systems not suitable both from the point of view of the suction method and from that of filtration.

Below you can appreciate the VS400M high flow dental aerosol extractor with hood diameter 35cm, note the speed of lateral suction despite the hood is not positioned close to the patient mouth and NOT above the patient as in other low flow products.

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications