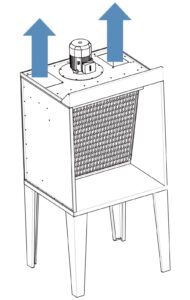

To obtain adequate protection, in addition to equipping themselves with the appropriate PPE, it is essential to use a system such as the suction bench, equipped with containment walls and a front suction, for maximum protection of operator and working environment.

In professional contexts and manufacturing often are carried out small processes such as paint retouches, resins, glues or other activities during which chemicals are used to be applied by gun or brush that release harmful agents such as solvents.

Being “small” activities normally for logistical or economic reasons, they are not carried out in real suction benches, but on normal work tables it is difficult to equip with suction solutions for the reduction of chemical risk.

However, as any RSPP or employer knows very well, these processes fall within the cases where the dlgs 81/08 requires to carefully evaluate the chemical risk, explicitly in Annex IV point 2: “presence in the workplace of harmful agents” with particular reference to:

In the case of the processes already described, the use of a mini suction bench, effectively solves the two main problems normally encountered, putting in safety the work environment and the operators:

| 1) The worktop integrated between the two side walls, allows to “contain” the exhalations or micro-dust produced.

2) The front suction wall creates an air flow in the direction opposite to the respiratory tract of the operator, preventing the pollutants from going towards him (red arrows). |

|

This type of solution also meets the UNI EN 1093-4 standard “Efficiency of the collection of a suction system” and the suction speeds of minimum 0.5 m/s on the front of the suction bench (where there are arrows) is suitable for activities such as low pressure spray painting, filling of containers (racking), manual bonding, resining of electronic components, or manufacturing.

The suction booth is equipped with two filter stages designed for the applications described above that do not normally release large quantities of products over time and therefore do not fall under regulations with particular efficiency requirements:

– Stage 1: composed of a layer of sturdy non-flammable special paper with offset holes housed in special guides and fixed laterally with screw paper holder that makes the replacement very easy. This particular system allows the contained air to change direction so that the pollutant particles are pushed outside on the absorbing wall of the filter. Exit wounds are self-cleaning.

– Stage 2: composed of flat filters thickness 23 mm made with frame in U-shaped galvanized sheet, two containment nets of electrowelded galvanized steel wire and filtering media in glass fibres with progressive density with weight 200 gr/m2 and thickness 50 mm.

| The extractor integrated in the upper part of the suction cabin guarantees an adequate flow rate and above all a sufficient pressure so as to be able to effectively aspirate and expel outside the premises what is aspirated, in compliance with the relevant regulations. |  |

The use of a mini suction bench, from the point of view of occupational safety, reduces the possibility of chemical accidents. We know fortunately they are not very numerous but, if they happen, they are often very serious or deadly and can involve different people and the environment of the company. The hazards arising from chemical agents are not immediately apparent and perceptible; as indicated by professionals, it is necessary to avoid underestimation of the risk and to implement appropriate and necessary preventive measures.

In the event that the painting operations or the exhalations produced are in large quantities, it is definitely necessary to consider the use of an industrial painting bench, designed in operation and with dimensions depending on the work carried out.

Useful links:

-wikipedia: unique text on safety at work

-puntosicuro: safety at the workplace

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications