Since a few weeks with the growth of the second wave of the pandemia, the mobile extractor of high-flow aerosols, is used with new applications in hospital and polyclinic facilities Italians in support of health operators, increasingly dramatically infected during assistance activities.

The mobile extractor of medical aerosol from the Airsafe line, designed in late March to reduce the coronavirus risk of dentists and dental operators, a few weeks after the second wave of the pandemia, is used with new applications in the Italian hospital and polyclinic structures in support of health care workers, more and more dramatically infected during the assistance activities.

In fact, the personnel involved in the care are particularly exposed, as the infection can spread through inhalable respiratory secretions through the nose, mouth and eyes.

The procedures considered high risk are:

Thanks to the patented filtration and the high suction rate, the high flow mobile extractor is able to drastically reduce the risk of infection for doctors and operators exposed to aerosol particles, exhale from patients during simple diagnostic examinations, up to the most burdensome situation: the Covid departments equipped in facilities not equipped with adequate general ventilation.

In this last emergency scenario, often organized in premises already served by HCAV systems, the use of the mobile extractor of medical aerosol with recirculation in the environment, has the considerable advantage of keeping unchanged the delicate pressure and energy ratio maintained by the systems, which is not possible with fans that expel air outside.

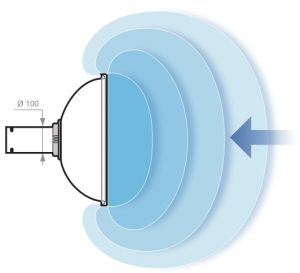

FunctioningThe extractor of aerosol thanks to the high operating flow and the circular hood, creates a negative pressure zone of about 300 mm that draws the air and particles with an airflow of about 2 m/s towards the extractor, combating environmental pollution. The multiple filtration stages certified with final grade H14 or U15 depending on the versions guarantee the abatement of up to 99.9995% of airborne particles according to the EN 1822 standard that regulates the individual test of each filter produced. This type of mechanical filtration defined as “absolute” and widely used in hospitals, becomes even more reliable thanks to the stage of pre-Separation of the wet parts patented with the system Airsafe® which guarantees operators the possibility of sanitizing the machine using normal products simply by vaporizing them in the extraction hood.

|

|

More information about the Airsafe line of extractors is available here or by filling out the form at the bottom of the page.

Secureair® – Technical office

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications