The FEB suction bench is to be used to vacuum dust generated during post-processing operations such as cleaning and blowing parts with compressed air, to prevent it from being breathed in by operators and polluting the work environment, as it is very volatile.

Applications

The FEB15 suction bench is designed to protect the operator and the environment from dust produced during the post-processing process of 3D printed parts such as blow molding, dust removal, and quality control.

FEB15 suction bench is ready to use, it is not necessary to connect it to suction systems, fans, or external filters, nor to make complex electrical connections, as it is complete with electrical panel with electronic control unit for monitoring filters. The pneumatic connection includes a pressure regulator.

Thanks to the wheels for handling, and the silencer for exhaust air in the environment it becomes a very flexible tool in production, completely independent without having to connect a chimney for ejection into the atmosphere.

Construction

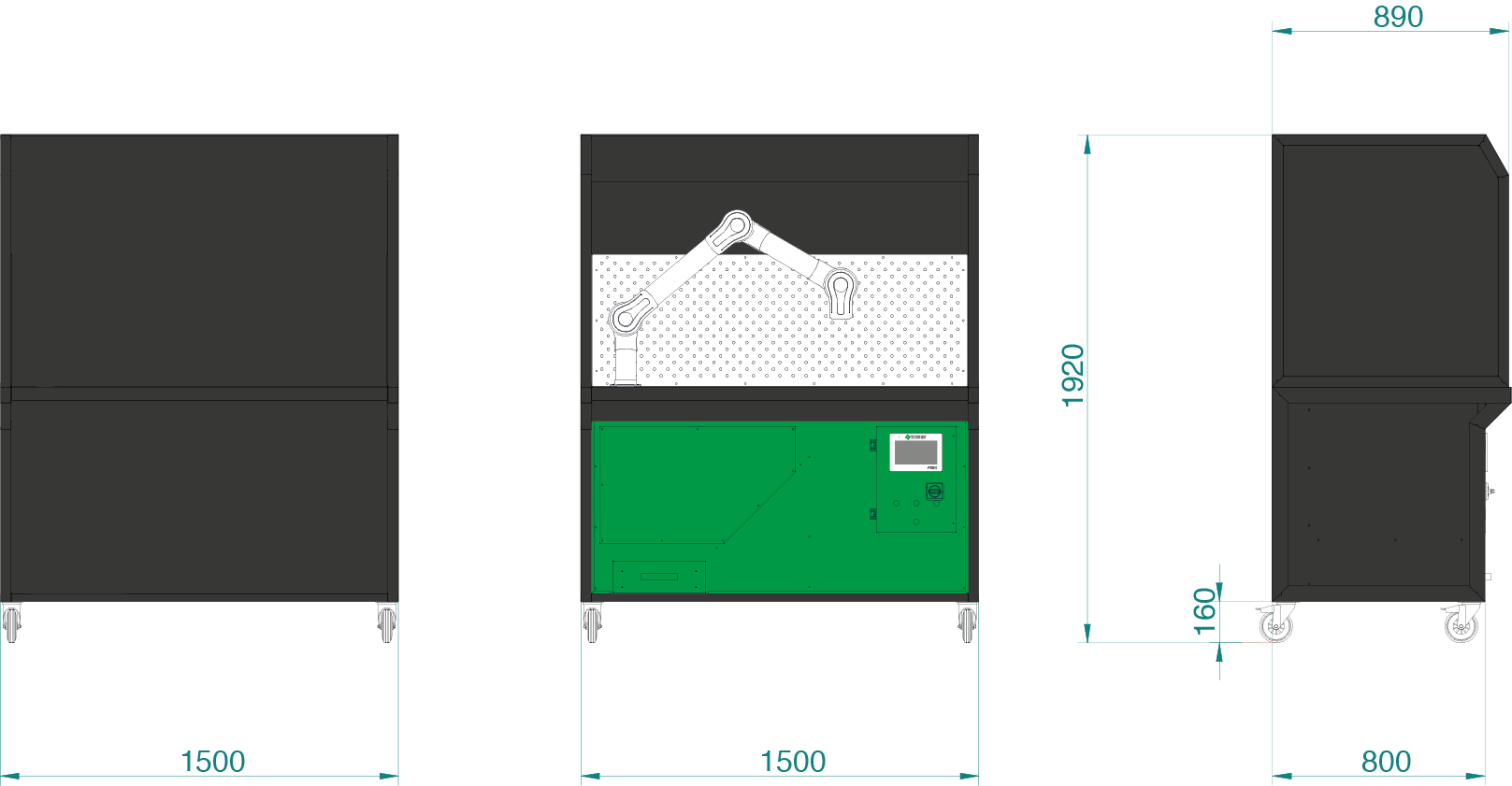

The suction bench is made with modular panels made of sturdy painted sheet metal.

Integrated extractor located inside the bench structure, specifically designed for the type of use required.

Integrated led lighting, with switching off by operator panel.

Switching the ventilation on and off as well as monitoring the filter parameters are controlled by a touch display located on the counter front.

On the rear side of the machine there is a filtered air exhaust grille or on request a rectangular section outlet to connect the exhaust pipe.

The support and work surface is made with reinforced structure and lateral uprights outside the bench to unload the weight on the floor.

Top and front suction wall are drilled in order to evenly distribute the suction and built with a structure in zinc-plated sheet of the first choice and adequate thickness (on request AISI or painted).

Dust collection drawer.

Filter section composed of cartridge filters with pneumatic cleaning, suitable for the most demanding applications.

Optional internal suction arm, designed to effectively aspirate during operations that generate localized fumes.

How does it work?

Simultaneous suction from the worktop and front wall ensures optimal capture of fumes and dust that is subsequently filtered by cartridges integrated in the cabin, with a final filtration degree of 99.99% HEPA.

Thanks to the special "ARMSEL" function in case of suction need at a specific point of the plane, it is possible to concentrate part of the intake flow from the articulated arm, drastically reducing the dispersion of the fumes that are sucked at the source.

| Power (kW): | 2.2 |

| Nominal flow rate (m3 / h): | 3300 |

| Noise (Db (A)): | 73 |

| Filter surface area (m2): | 40 |

| Filtering efficiency (%): | > 99% |

| LCD Display : | you |

| Power supply (V): | 220 |

| Power supply (Hz): | 50 |

| Cartridges (num.): | 4 |