The SBC suction bench is available in 4 different sizes ranging from 1 to 3 meters. Designed to suck fumes and dust during professional operations that produce emissions dangerous for operators and the working environment as very volatile. This version is suitable for intensive use thanks to cartridge filters with compressed air cleaning, which ensure the restoration of maximum filtration efficiency at the end of the cycle and a long life in times.

Available versions

SBC - with polyester filters

SBCH - equipped with HEPA H13 filtration

SBCX - with antistatic polyester filters and ATEX motor

Professional operation with pneumatically cleaned filters

Cartridge filtration with pneumatic cleaning, ensures the operation of the vacuum bench without the need to change filters often and provides 99% filtration efficiency even with the heaviest applications.

The SBC suction bench is ready to use; there is no need to connect it to external suction systems, fans or filters, nor to make complex electrical connections. The pneumatic connection includes a pressure gauge as standard, located on the front of the bench near the operator panel.

The SBCH suction bench, on the other hand, is also equipped with HEPA H13 filters.

Some important facts about HEPA filtration:

The term HEPA filter (from High Efficiency Particulate Air filter) refers to a special high-efficiency filtration system for fluids (liquid or gas).

HEPA filters are part of the category of so-called "absolute filters" justified by the fact that HEPA filters have a high filtration efficiency, Specifically, HEPA filters are classified according to the filtration efficiency of 0.3 µm particles, according to the UNI EN 1822 standards. In fact, they are grouped into 5 classes (H10 to H14) with increasing performance characteristics.

They are tested by the method of dispersion of a dioctylphthalate aerosol (DOP test: the calculated efficiency is > 99.999 % with particles of 0.3 µm diameter (0.001% penetration).

Main features of all SBC suction benches:

Sturdy structure composed of modular panels made of thick press-bent galvanized sheet metal, bolted together, without welding, for long service life.

Adjustable feet (or wheels on request)

Centrifugal fan located inside the bench structure, in the clean area downstream of the filters, designed for the type of use required.

Turning the ventilation on and off is controlled by an operator panel located on the front of the bench. Through the display it is possible to view the status of the filters and set filter cleaning parameters.

On one side of the bench is the filtered air outlet with rectangular section. On request suction connection for connecting the bench to the centralized system or curve for reintroduction into the environment.

The suction support and work surface is made of uniformly perforated reinforced structure, attached to side uprights outside the bench for optimal weight discharge *

The suction front wall is constructed of first-rate galvanized sheet metal of adequate thickness (upon request front in anti-rebound wire mesh to cushion any grinding chips).

The two slag collection drawers are made of press-folded galvanized sheet metal, equipped with a practical handle for removal.

The filter section of the SBCH bench consists of the latest generation of cartridge filters, made of polyester with 99% efficiency, equipped with pneumatic cleaning, suitable for the heaviest applications.

Compressed air connection: the suction bench is equipped as standard with a pressure regulator with 3/8" connection. Terminal with 3/8" male is required for connection.

* on request reinforced top for higher loads

Technical insight on suction benches with integrated filters.

If equipped with wheels for handling and silencer for exhaust air in the environment becomes a very flexible tool in production, completely independent without the need to connect a chimney for ejection into the atmosphere.

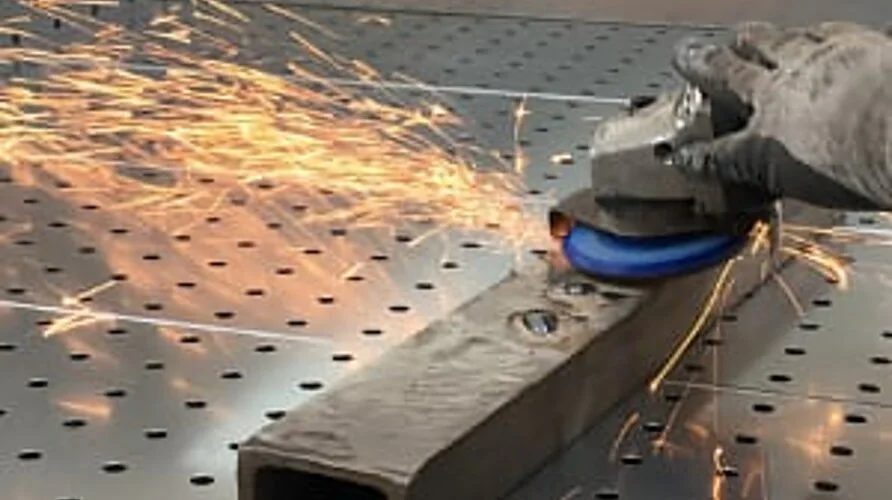

Example of grinding suction.

A series of internal baffles and standard metal mesh panels protect the cartridges from sparks while drastically reducing the risk of fire.

| Code | Maximum load (kg / m2) | Power (kW) | Nominal flow rate (m3 / h) | Useful pressure (Pa) | Noise (Db (A)) | Filter surface area (m2) | Filtering efficiency (%) | Power supply (V) | Power supply (Hz) | Cartridges (num.) |

|---|---|---|---|---|---|---|---|---|---|---|

| - SBC100000000024 | 150 | 2.2 | 2500 | 600 | 73 | 20 | > 99% | 400 | 50 | 4 |

| - SBC10X000000024 | 150 | 3 | 2500 | 600 | 73 | 20 | > 99% | 400 | 50 | 4 |

| - SBC150000000024 | 150 | 2.2 | 3300 | 600 | 73 | 32 | > 99% | 400 | 50 | 4 |

| - SBC15X000000024 | 150 | 3 | 3300 | 600 | 73 | 32 | > 99% | 400 | 50 | 4 |

| - SBC200000000024 | 150 | 2.2 | 5000 | 600 | 78 | 40 | > 99% | 400 | 50 | 4 |

| - SBC20X000000024 | 150 | 3 | 5000 | 600 | 73 | 40 | > 99% | 400 | 50 | 4 |

| - SBC300000000024 | 150 | 2.2 | 6500 | 600 | 78 | 64 | > 99% | 400 | 50 | 4 |

| - SBC30X000000024 | 150 | 3 | 6500 | 600 | 73 | 64 | > 99% | 400 | 50 | 4 |

| Code | Drawer (L) | A (mm) | a (mm) | B (mm) | b (mm) | c (mm) | d (mm) | H (mm) | h (mm) | H1 (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| - SBC100000000024 | Frontal | 1000 | 930 | 1100 | 950 | 450 | 160 | 1400 | 1000 | 2000 |

| - SBC10X000000024 | Frontal | 1000 | 930 | 1100 | 950 | 450 | 160 | 1400 | 1000 | 2000 |

| - SBC150000000024 | Frontal | 1500 | 1430 | 1100 | 950 | 450 | 160 | 1400 | 1000 | 2000 |

| - SBC15X000000024 | Frontal | 1500 | 1430 | 1100 | 950 | 450 | 160 | 1400 | 1000 | 2000 |

| - SBC200000000024 | Frontal | 2000 | 1930 | 1100 | 950 | 610 | 500 | 1400 | 1000 | 2000 |

| - SBC20X000000024 | Frontal | 2000 | 1930 | 1100 | 950 | 610 | 500 | 1400 | 1000 | 2000 |

| - SBC300000000024 | Frontal | 2805 | 2740 | 1100 | 950 | 610 | 500 | 1400 | 1000 | 2000 |

| - SBC30X000000024 | Frontal | 2805 | 2740 | 1100 | 950 | 610 | 500 | 1400 | 1000 | 2000 |

| Name | Code | Price | ||

|---|---|---|---|---|

|

Wheel kit for SB benches | KITRUOTESB00000 |

From:

225,00 €

|

|

|

Vertical air outlet channel H1 mt suction desks | KITSCARICAMBSBT |

From:

331,00

€

|

|

|

Round flange for exhaust air adaptation on silent curve | FLTNASCURSB0000 |

From:

129,00

€

|

|

|

Pair of non-suction side bulkheads for SB benches | PLSB00000000000 |

From:

154,00 €

|

|

|

Anti-sparking front wall for SBC benches | PARSB0000000000 |

From:

293,00

€

|

|

|

Side and top casing for SB benches | CSUSB0000000000 |

From:

429,00

€

|

|

|

Non-suction front extension for SB benches all | PFNASBT00000000 |

From:

207,00

€

|

|

|

Exhaust kit with integrated HEPA filter for SBV benches | KITSCASBCVHEPA0 |

From:

1.094,00

€

|

| Name | Code | Price | ||

|---|---|---|---|---|

|

Polyester cartridge filter kit for SBC benches | KITCARP000SBC00 | 295,00 € |