The reasons for the success of the suction benches in both small and large companies can be summarized in this article and are both technical and practical, with final and perhaps decisive addition represented by a solution/ price ratio increasingly affordable.

The suction bench has established itself in recent years as an exceptional tool for protecting the respiratory tract and the working environment in those professional contexts where operations are carried out that produce powders of any size, from the heaviest to the very volatile ones just a few microns in size.

The reasons for the success of the suction benches in both small and medium-large companies can be summarized below, they are both technical and practical, with final addition and perhaps decisive represented by a solution/ price ratio increasingly affordable, whereas you can buy like other equipment directly online from manufacturers without intermediate commercial steps.

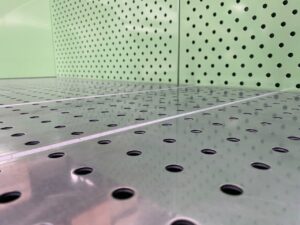

Perceived suction flowVery often our customers when they come to view the suction benches in production, they instinctively put their hand on the work surface of the suction bench that in the standard versions is made as in the photo on the right, with a series of circular holes specially sized to ensure a homogeneous air flow on the whole suction plan. However, leaning your hand to feel “how much it sucks” as you would with a hood or a classic extractor, you are usually a little puzzled because apparently there is little suction at that point, although the bench works perfectly. On the contrary, they are happily impressed when we tell them to remove the hand from the plane and open their fingers, in this way it is possible to perceive a high suction speed, the famous perceived suction flow by the operator if the suction bench is correctly designed. |

|

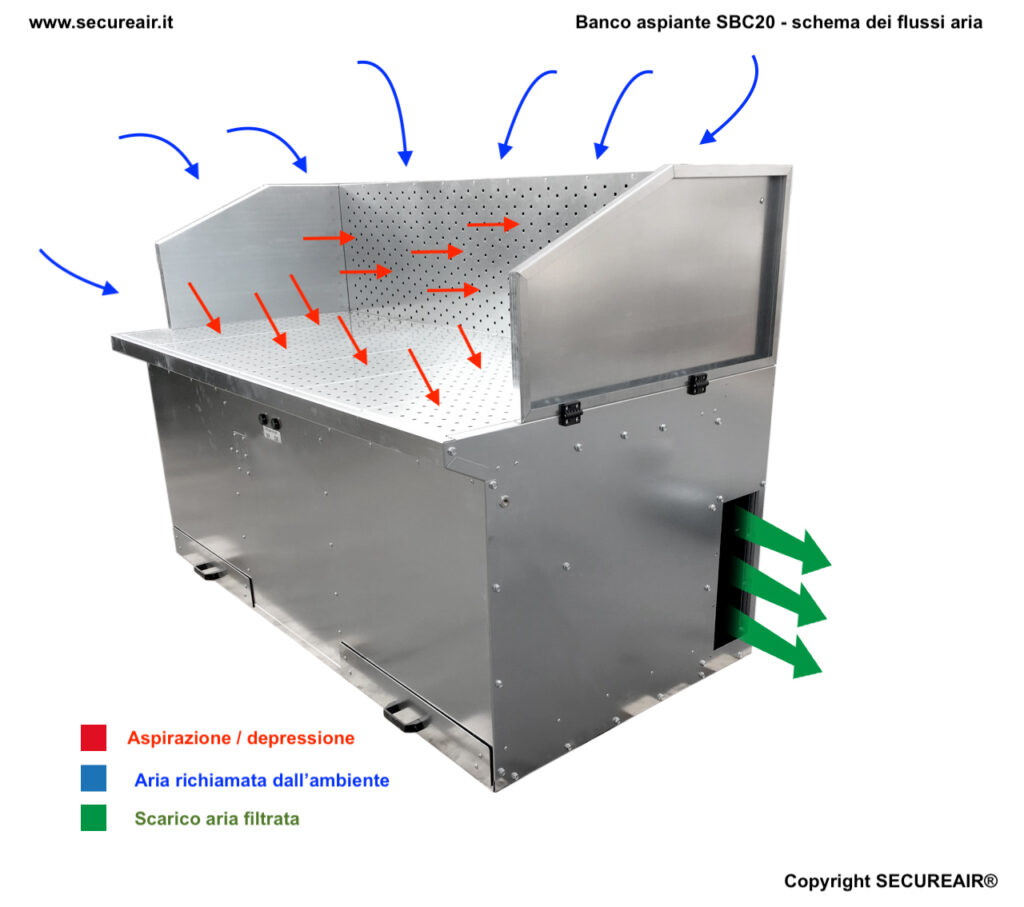

Since giving the same suction power as a normal extractor on each hole would require enormous working capacities, resulting in design and cost problems, the designers have solved this problem by working on the concept of widespread suction that as you can see from the graphic representation below, two fundamental results are achieved that justify the investment in a suction bench if you have a processing of any type that produces dust and fumes:

From the image above you can also notice (the green arrows) the convenient low side exhaust air that is filtered with efficiency up to 99.9% in cartridge versions. This output flow can be channeled for external ejection or conveyed in one silenced exhaust which is a very versatile solution of the suction bench on wheels, easily re-positioned in production where necessary.

The aspiring bulkheads, often seen as an “impediment” by operators are of fundamental importance because they protect the suction flow from lateral air currents that are normally present in working environments especially in summer and that having a horizontal speed higher than the suction tend to “remove” airborne dust from the bench before it is sucked.

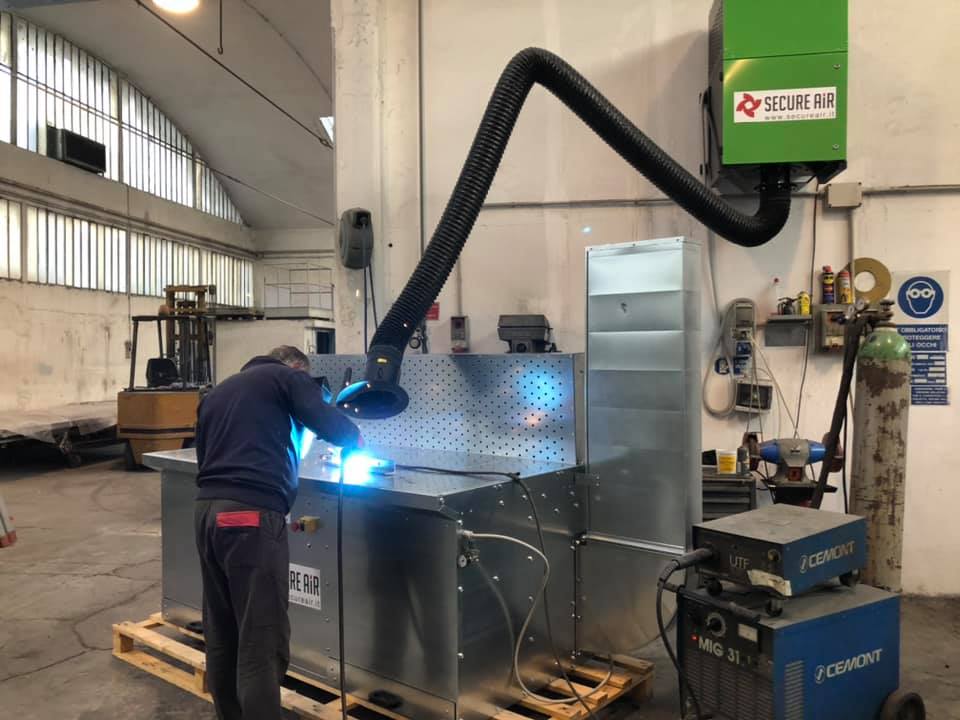

Welding fumes or other processes are also sucked from the top and from the front bulkhead, however in case they are very hot or have a high climbing speed due to the temperature or other processing characteristics, We recommend they are picked up by a suction arm held in support of the bench and to be used when the production situation requires it.

In the picture below an unbeatable team consisting of suction bench and purifier with arm, wall or mobile.

Do not hesitate to contact us for more technical information or for particular applications.

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications