Often installed in welding areas or on portable machines, The suction arm is the basis from which any good extraction system for welding fumes or other similar processes starts and has as a fundamental characteristic the one required by all regulations and even earlier by the best suction techniques: the collection at the source of the pollutants produced.

No other suction system, industrial hood or pipe, can protect workers better than the suction arm in the metallurgical industry. This is because it prevents the accumulation of welding fumes, oil mist or processing dust.

Obviously the use of the flexible suction arm or rigid tubes is a good method to suck fumes and dust when working on small or medium-sized objects, more or less easily accessible from the wall or column on which the suction arm is fixed, which must be able to operate comfortably in the operator’s working area.

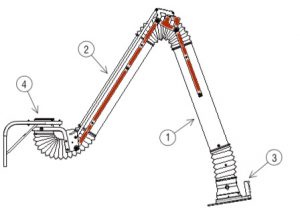

| From the drawing on the right you can see the basic elements that make up any suction arm. However, there may be some dimensional differences depending on the manufacturer, but they are usually all made up of:

1. Suction pipes, that is the pipes where the fumes and pollutants sucked in by the arm |

|

The suction arm is distinguished by these four main technical characteristics:

|

|

Last point that we want to address in this technical article is that of the two possibilities of use/ installation of the suction arm:

|

|

The recommended rated minimum flow rate for a suction arm is from 1200 to 1500 mc/h depending on the type of pollutant to be sucked, if it is hot fumes you can consider the lowest value, in case there are microdust or a lot of smoke better stay on the high value.

Do not hesitate to contact us for more information!

Secureair – Technical Office

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications