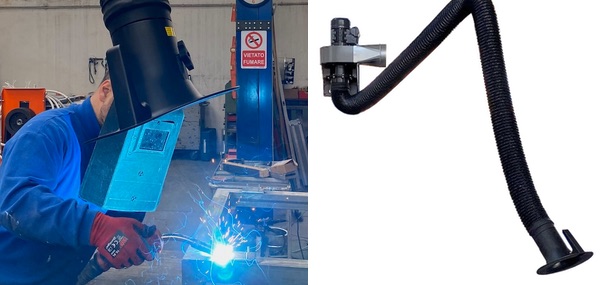

Simple, effective and inexpensive. The wall-mounted fume aspirator is ideal for fixed stations where welding or other professional processes are carried out that produce pollutants within a radius of 4 meters from the wall.

We have already covered the topic of smoke extractor in many articles, but this time we want to focus on a simple and effective solution, the wall-mounted smoke extractor with arm and integrated fan.

This protective equipment is ideal for fixed locations where welding or other professional processes are carried out that produce pollutants more or less in a radius of 4 meters from the wall, activity in a well-defined position within a production layout.

We can therefore use a fixed and not portable fume extraction system that guarantees us some strategic advantages:

The classic application is for welding fumes suction but this solution can also be applied to suck vapors, odors, fumes provided they are not potentially explosive.

As you can see from the video below just place the suction arm as close as possible to the working point and smoke protection is ensured.

Some advice for maximum efficiency:

The answer is absolutely yes, indeed respects them strictly for two reasons:

1) Close-up capture as indicated by Legislative Decree 9 April 2008, known as law 81.

2) Fumes and aspirated pollutants are expelled outside the working area; remember that it is not allowed to recirculate in the environment because the wall-mounted fume extractor in this case has no filters and because in the case of fixed systems the expulsion to the outside is always required. It will then be necessary to connect the extractor to a line of pipes.

The wall-fume extractor must be installed at about 2.5/2.7 meters from the ground and has a working radius of 3 or 4mt depending on the versions. The installation is very simple and is divided into three phases:

The wall fume extractor is composed of:

| – Suction arm with self-supporting structure built to last over time and ensure maximum manoeuvrability always in perfect balance and black flexible suction pipe in special PVC reinforced with steel resistant to high temperatures, easy to replace in case of maintenance.

– Truncated-conical spiral hood with rectangular base, made of plastic. The screen is equipped by delimiting the suction area significantly increases its effectiveness. Complete with handle and on request adjustment damper – Sturdy, welded and painted steel shelf for fixing the suction arm and fan to the wall or column – High efficiency centrifugal fan already mounted on the shelf, directly coupled to 1.5kw single-phase electric motor 220/1/50 |

|

For more application tips contact our technical department.

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications