Even if the welding fume extractor is an apparently simple and low-tech equipment, the most recent developments from a legislation point of view regarding air filtration for the protection of operators, have sensitized companies towards a more thorough research

Even if the welding fume extractor is an apparently simple and low-tech equipment, the most recent developments from a legislation point of view regarding air filtration for the protection of operators, have sensitized companies towards a more thorough research, destined both for the latest generation of mobile fume extractors and for smoke aspiration systems equipped with filtration for reintegration or emission into the atmosphere.

Most of the welding fume extractors, especially in version mobile or trailer-mounted, however, they are still produced with obsolete filtration efficiencies like the old F9, we therefore advise you to start by: always checking and asking for the final grade of filtering efficiency of the product. You don’t know what it is about? Great, this article is for you!

From a legislation point of view, it is important to remember that since 2017 ISO 16890:2017 has been introduced and the filters will no longer be divided into Coarse efficiency classes (C), Medium (M) or Fine (F) as in the past, but they have been divided into 4 filtration classes, according to the particle size or particulate matter:

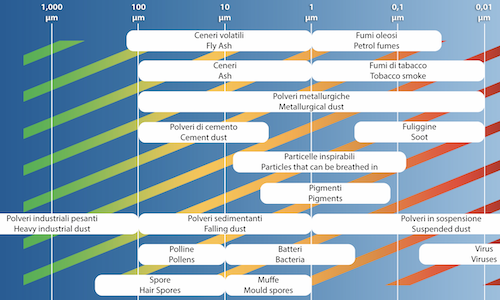

This new distinction came about as a result of joint studies by the scientific and medical community and by the WHO (World Health Organization), which together found and confirmed the increasing danger to human health caused by particles less than 1 micron in the air, in our case especially in the production areas of carpentry, workshops and industrial contexts.

Often companies and operators before choosing a welding fume extractor, underestimate the problem of the size of particles and fumes, because they “see” little and do not remain deposited at the end of the day; nothing more wrong, because you should be aware that the fumes from metallurgical processing range from a maximum size of 100µm (1/10 mm) up to the minimum of 0.01 µm, as can be seen from the table below. This means that all filters with efficiency lower than ISO ePM1 are not able to stop welding fumes, remember that!

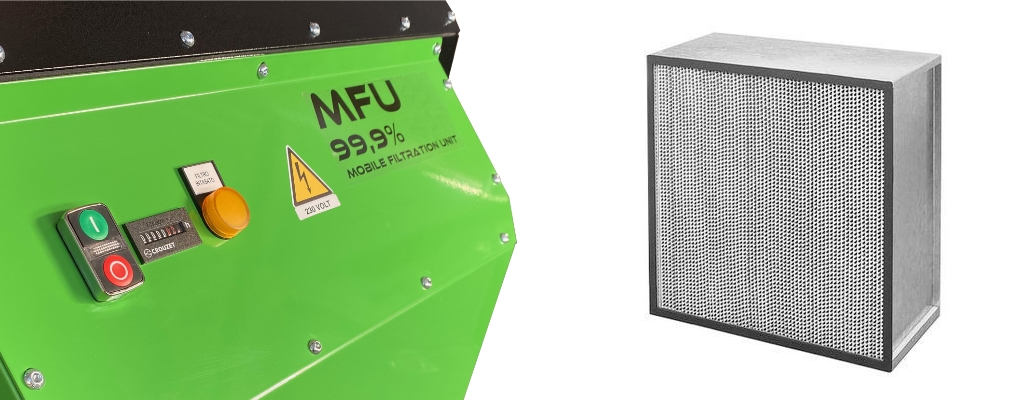

So what are you waiting for? Check out our range of mobile welding fume extractors with HEPA technology:

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications