Welding fumes are dangerous because they arise from a combustion where the objects to be welded are brought to temperatures close to that of melting, in order to form the welding seam. During this phase welding fumes are released, which depending on the type of processing and metals can also be carcinogenic.

The new generations of welders, thanks to the training and increase of the culture related to safety in the workplace, are increasingly sensitive to respiratory risk factors. Fortunately for our environment the awareness is spreading that welding operations, if not filtered, generate several health problems related to gases and vapors generated such as:

Close suction is always the best solution and consists in capturing the fumes near the welding. The only products that allow this type of solution are those that use the suction arms, fixed or mounted on board a welding fume extractor. The arms work well even with reduced air flow compared to wall fans or torrini roof fans.

Due to several poor quality products on the market (because “the important thing was to have it and show it even if it does not work”) portable or trolley welding fume purifiers do not enjoy an excellent reputation with local authorities, which often do not accept them unless they have the following characteristics:

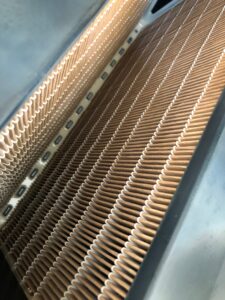

We post below two photos related to the second filter stage and the HEPA filter of a MFU welding fume extractor taken after only 18 hours of operation!! As you can see from the color (which was white) the filter fabrics are impregnated with particles that otherwise would have remained in the working environment and…you breathe.

Secure air – technical Department

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications