Thanks to the suction torch, the welding fumes are sucked into the source, with a “mini” suction hood positioned on the torch. Let’s see all the features.

The suction torch is very common as a system of extraction of welding fumes in Northern European countries and generally in the “advanced” markets where there is a high sensitivity to the health protection of the welder and at the same time to energy savings. It is about a technical solution that has many advantages than the classic smoke suction systems, even if being technologically advanced requires a good technical culture and the willingness to change some process habits that the welder is not always willing to do.

| Typical action of the suction torch: the welding fumes are sucked into the source where they are produced, thanks to a “mini” suction hood positioned on the torch.

This obviously makes the system unique because if the welding fumes are picked up before, obviously they can not disperse after, so we will no longer have the classic smoke in mid-air around the workshop. The high-pressure suction effect that passes through the suction torch along its entire length therefore simultaneously performs two decisive functions:

The welding fume suction torch must of course be connected via a 50 mm diameter hose to a portable or fixed suction system that creates a vacuum to capture the fumes through the torch. |

With regard to the decrees on occupational hygiene, the suction torch, like almost all the systems proposed by Secureair®, allows to stay below 70% of the maximum levels of pollution (TLV 5 mg/mc) established by law and therefore well below the limit of “area of action” within which preclinical signs of occupational disease cannot be detected. It should be noted that large companies require safety margins of 50% for air treatment equipment compared to the maximum limits allowed by law. For more information on TLVs see here.

The technical solutions are normally of two types, both require high pressure suction systems, different from each other only according to how many torches work in the department.

|

|

|

|

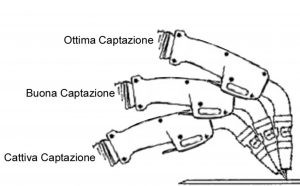

In order to obtain the best result, both for the fume extraction and for the technical features of the welds, it is advisable to use the following precautions:

|

|

| The torch should always be held at an inclination of approximately >15° <45° (EN 60974-7 standard) compared to the melting bath to get the best suction together with better welding quality. |

|

| The maximum distance between the gas nozzle and the melting bath must always be kept below 1 cm (EN 60974-7 standard), especially for corner welding, this to avoid the risk of porosity or oxidation in welding. |

|

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications