During the welding of metals, fumes, dust, and gases are produced containing dozens of different and harmful chemicals that remain suspended in the air in the form of micro-powders metal particles or metal derivatives (for example oxides), but also dust and fumes from filler materials (electrodes, rod electrodes, lead, welding powder, etc.) or these are removed from the recoating as paints, coverings, and detergents.

During the welding of metals, fumes, dust, and gases are produced containing dozens of different and harmful chemicals that remain suspended in the air in the form of micro-powders metal particles or metal derivatives (for example oxides), but also dust and fumes from filler materials (electrodes, rod electrodes, lead, welding powder, etc.) or these are removed from the recoating as paints, coverings, and detergents.

It is therefore of paramount importance to use a welding fume purifier designed for the suction and filtration of fumes and micro-dust generated during metal welding processes, so that they are sucked before reaching the respiratory tract of the operator.

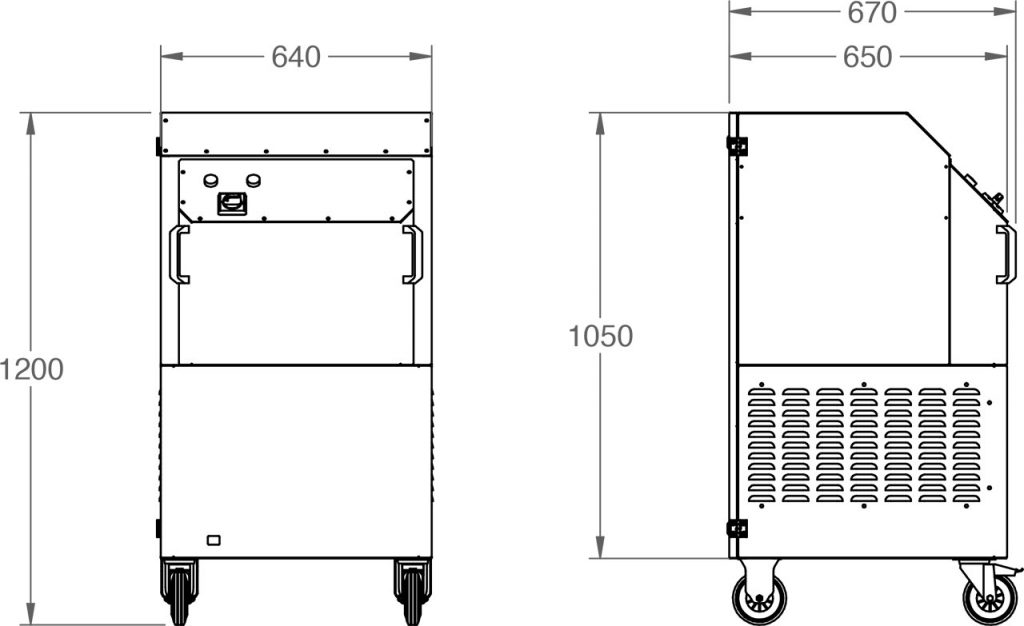

The MFU welding fume extractor thanks to the compact size, to the wheels, and handles can be easily moved near the processing to be carried out and then suck the fumes using the practical self-supporting suction arm that, thanks to its hood with handle, sucks the welding fumes directly at the source.

This welding fume extractor sucks from the top hole the pollutants that pass through the system downwards and are purified to 99.9%

At this point the clean air is returned to the environment through grids positioned at the bottom of the machine.

The level of clogging of the filters is monitored by a control that alerts with a light signal when it is necessary to clean or replace the filters, so as to avoid continuing work without air filtration.

The light and practical suction arm mt.3 long with hood, handle, and flexible pipes moves effortlessly.

Nominal flow rate: 1.500 mc/h

Motor power: 1.5kw 220/1/50

Residual pressure: 500 Pa

Stage 1 filtration: spark-proof metal filter eff. G3

Stage 2: acrylic filter eff. G4 in accordance with EN 779:2012

stage 3: absolute filter eff. H13 99.95% @ MPPS in acc to EN 1822:2009

Stage 4: active carbon filter for odors

Total weight: 110 kg ca

Reference standards: UNI EN ISO 15012

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications