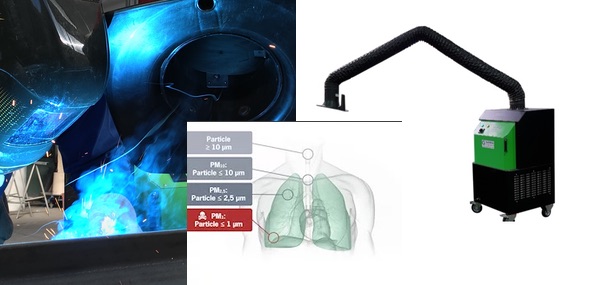

Many users have written us asking to explain in detail why they should trust an equipment that sucks fumes and then re-imports the clean air inside with filtration declared to be 99.95%. Here they are satisfied!

In our blog we have already written several articles about the welding fume extractor in a portable version with integrated filtration, also known as mobile purifier or wheeled purifier.

Many customers before buying it have written asking us to explain in detail why they should trust an equipment that sucks the fumes and then re-imports the clean air inside with filtration declared 99,95% and to know which filters are used inside, to better understand how the welding fume extractor can effectively filter and break down fumes and micro dusts dangerous for the welder.

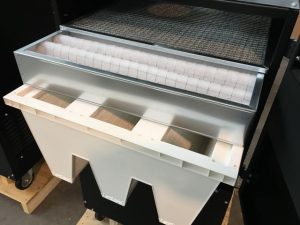

| The first fundamental concept, is that no mechanical filter alone is able to directly purify 99.9% of the welding fumes, in fact the professional mechanical air filtration is always composed of a series of filters one after the other, in order to create a “sequence”.

Otherwise in the finer filter it would clog very quickly without the “protection” of the previous ones. You can see well in the photo on the right as from top to bottom there are three filtering stages with last in the bottom the largest and most important. |

|

But let’s go back to the main topic of this article and let’s see in detail the path that make fumes and dust after they have been sucked by the hood/ suction arm:

| Efficiency grade EN ISO 16890: Coarse

Composed of a metal filter with frame and internal nets in galvanized steel, it forms a real mesh/ sieve designed to stop the largest dust, the sparks and in general to protect the filters later stages that being finer would be immediately saturated by dust. Just because coarse and metallic can be cleaned several times by washing it but without exaggerating with aggressive detergents or high pressure washers otherwise the internal links can loosen losing the protective function. |

|

The cost is usually low, but do not underestimate this filter because it is very important for teamwork in stopping welding fumes by protecting those after.

| Efficiency degree EN ISO 16890: Coarse 45% Filtration class EN779: G4 Composed of a filter with frame and metal mesh for containment of a septum in synthetic average, able to break down the average dust with a gravimetric efficiency of 90% which means filtering at least 90% of the powders with size 2 microns and obviously higher, a fair amount of work to protect the next final stage. Also this stage would be theoretically washable and blowable but we do not recommend it because often with welding fumes it becomes loaded with even oily residues as can be seen in the photo. |

|

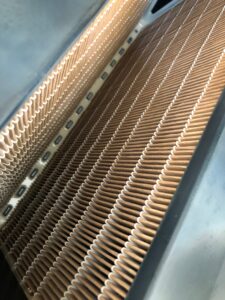

| This filter in technical jargon known as “absolute” does the real work that then protects our lungs from the smallest particles, namely harmful micro dust.

Efficiency degree EN 1822: 99.95% MMPS or only 0.05% of the smallest particles The filter material of this precious filter is made of glass fiber, with thermoplastic wire separators. The absolute filter cannot be cleaned and blown and ATTENTION its life depends on how good the user is at checking, cleaning and often replacing the first two filter stages. |

|

Thanks to this sequence of filters with final efficiency HEPA H13 99.95% the MFU series welding fume aspirator can be used for the separation of carcinogens, for example for welding stainless steel and for this reason is labeled W3 according to ISO 15012-1.

| Seeing is believing

Here on the right you can see the color of the filters stage 2 and stage 3 described above, after just 18 hours of operation, here the link to the full article. And in the videos under the welding fumes extractor in action during electrode welding of large hydraulic fittings, one of the most “smoky” of all! Have a good job!

|

|

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications